New Products

Find Alloy Wire, Nickel Alloy Wire, Alloy Steel on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

Model No.: N07718 Inconel 718

Element | Content |

Ni+Co | 50 - 55 % |

Cr | 17 - 21 % |

Fe | BAL |

Nb+Ta | 4.75 - 5.5 % |

Mo | 2.8 - 3.3 % |

Ti | 0.65 - 1.15 % |

Al | 0.2 - 0.8 % |

Property | Metric | Imperial |

Density | 8.19 g/cm3 | 0.296 lb/in3 |

Melting point | 1336 °C | 2437 °F |

Co-Efficient of Expansion | 13.0 µm/m.°C | 7.2x10-6 in/in.°F |

Modulus of rigidity | 77.2 kN/mm2 | 11197 ksi |

Modulus of elasticity | 204.9 kN/mm2 | 29719 ksi |

Condition of Supply | Heat Treatment (After Forming) | |||

No.1 Spring Temper/Spring Temper | 1. Solution Anneal at 980°C (1800°F) for 1 hour and air cool and 2. Age harden at 720°C (1330°F) for 8 hours and furnace cool to 620°C (1150°F) and hold at 620°C (1150°F) for a total age hardening time of 18 hours and air cool. | |||

No.1 Spring Temper/Spring Temper (NACE MRO175) | 1. 1010°C (1870°F) 2 hours and air cool and 2. 790°C (1455°F) 6 hours and air cool. | |||

Condition | Approx Tensile Strength | Approx Service Temp. | ||

Annealed | 800 - 1000 N/mm2 | 116 - 145 ksi | - | - |

No.1 Spring Temper | 1000 - 1200 N/mm2 | 145 - 175 ksi | - | - |

No.1 Spring Temper + Annealed + Aged | 1250 - 1450 N/mm2 | 181 - 210 ksi | -200 to +550°C | -330 to +1020°F |

Spring Temper | 1300 - 1500 N/mm2 | 189 - 218 ksi | - | - |

Spring Temper + Annealed + Aged | 1250 - 1450 N/mm2 | 181 - 210 ksi | -200 to +550°C | -330 to +1020°F |

Form | Specification | Supply Form | Others |

Sheet | Thickness:0.40-4.75mm,General Width:1000,1219,1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B,2E |

Plate | Thickness:4.76-60mm,Width:1500,2000,2500mm,Length:3000,6000,8000,8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B,2E |

Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle,Square) | Solution annealing,descaling |

Forged barΦ26-245mm,Length≤4000mm | |||

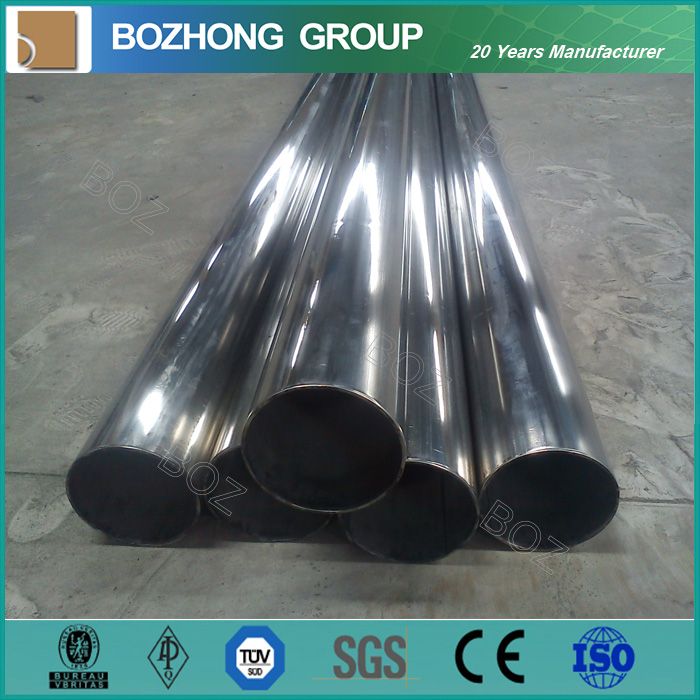

Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | Use for PHE |

Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | Use for PHE |

Wire | Outer diameterΦ0.1-13mm | Base on your requirement | |

Forged piece | roundness and square alloy | Base on your requirement | Steel, Alloy |

Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

Welding Material | Coil wire Φ0.90mm/1.2mm/1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

Straight WireΦ1.2mm/1.6mm/2.4mm/3.2mm/4.0mm | |||

Welding rodΦ2.4mm/3.2mm/4.0mm | |||

Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Product Categories : Nickle Alloy